Ballast Water Management System .

Developed by Techcross, ECS is a direct electrolysis BWMS and ECS-HYCHLOR is an indirect electrolysis system. These products utilize proprietary electrolysis technology to provide more perfect disinfection. They are top products recognized by the world for effective installation and swift customer response.

ADVANTAGES .

-

Low Power Consumption

Low Power ConsumptionTechcross BWMS uses the proprietary high-efficiency electrodes, which lead to an extremely lower power consumption compared to competitor's (ECS consumes 3.4kW and HYCHLOR consumes 5kW for 100 tons of sea water). That is, no additional devices are required to manage power consumption; the lower power consumption means savings on operating costs.

-

Convenient Installation

Convenient InstallationThe compact Techcross BWMS can be installed on various vessels regardless of type or size. The products can be flexibly installed in limited spaces, which means that minimal structural changes are needed, in addition to guaranteeing the best cost efficiency by reducing the installation time.

-

Low Maintenance and Operating Costs

Low Maintenance and Operating CostsTechcross BWMS treats ballast water only once during ballasting, which reduces operating costs and eliminates the necessity for regular part replacements. Techcross operates a reliability laboratory that enhances device and part durability to reduce maintenance costs.

-

Largest References

Largest ReferencesTechcross is an industry pioneer with the most installation cases. It is the first company in the industry that successfully installed explosion proof type of systems in large or difficult VLCC vessels. The ample references provide optimal installation solutions that will save customers time and money.

-

Global Service Network

Global Service NetworkTechcros operates global hubs in each continent to provide customized services to customers. Each hub is manned by Techcross employees and engineers who provide stable services. Key countries also host global training centers providing systematic training opportunities.

-

Continued Environmental R&D Investment

Continued Environmental R&D InvestmentTechcross is on the way to becoming a comprehensive environmental company from a marine environmental company. We are using proprietary technologies to various environmental projects, and through active R&D projects we offer new products and optimal solutions.

Tank Level Gauging System .

Only TECHCROSS’ technology, which can easily gauge the tank levels, saves the crew’s work time and trouble. HHT (Hand Held Terminal) is the main equipment of the TECHCROSS TLGS (Tank Level Gauging System), which makes it possible to calibrate the water level on deck. In particular, it has excellent compatibility with the TECHCROSS’ ballast water management system, so it can give the best effect when applied to ships that have already installed or are planning to install the ballast water management system. A total of three types of TLGSs are available, so it is possible to provide the products in response to various needs.

ADVANTAGES .

-

Simplicity

SimplicityThe crew can easily calibrate the water level on the spot using the HHT (a portable calibrating device).

-

Accuracy

AccuracyEven if there is an error in the transmitter, it can be efficiently applied to the tank with another transmitter. The HHT also makes it possible to adjust the transmitter on the spot.

-

Durability

DurabilityIt has passed the strict test, and a capacitive ceramic sensor has enhanced the reliable result value and corrosion resistance.

-

Integrated service

Integrated serviceThe electric signal (4~20mA) of the TECHCROSS TLGS can be monitored by connecting it to the TECHCROSS IBTV.

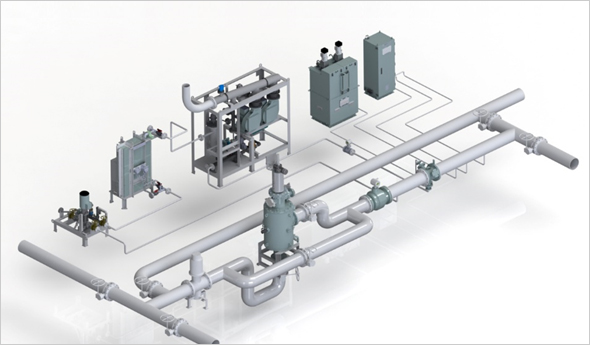

Integrated BWMS·TLGS·VRCS .

A one step further advanced one-stop solution for the ballast water management system.

IBTV, introduced by TECHCROSS, is a control platform that integrates a ballast water management system, a tank level gauging system, and a remote valve control system.

With a single operation, all equipment related to the ballast water management system can be controlled simultaneously.

BWMS

Providing the optimal solution with the global no.1 installation experience.

- Electro-Cleen™ System

- ECS-Hychlor™ System

TLGS

Possible to choose from 3 types according to customer needs.

- PNL (Pure Pneumatic type)

- ENL (Electro Pneumatic type)

- EPL (Electric Pressure type)

Workstation

The software that anyone can use easily with a user-friendly UI

VRCS

The valve lining system optimized for BWMS operation.

- HPU

- Sol’ valve cabinet

- Actuator

ADVANTAGES .

-

Full automation

Full automationIt makes it possible to experience simple and smart control by reducing the possibility of errors that could occur while operating multiple equipment at the same time, as well as reducing the labor time of crew members for operating individual equipment, which has been taken for granted so far.

-

One-stop service

One-stop serviceIn case of equipment problems, it took a lot of time and money to contact individual companies and adjust the schedule, but now it can be solved all at once by just contacting TECHCROSS. In addition, TECHCROSS’ AS service can be used anytime, anywhere.

-

Compatibility

CompatibilityFor the stable equipment use, TECHCROSS workstation and control panel are designed to be compatible with each other. Even if there is an accident, it is possible to use the equipment stably.

Alternative Maritime Power System .

The AMP system contributes to environmental protection and reduces carbon emissions from ships by utilizing an onshore power device instead of the ship’s generators. Techcross AMP system offers one-stop service based on the reliable know-how of global leader, providing optimal solutions regardless of the ship type and installation location. This aims to deliver cost-saving and convenience to customers.

ADVANTAGES .

-

One-stop service

One-stop serviceDrawing on accumulated know-how, Techcross offers a comprehensive range of services, including onboard surveys, installation, commissioning, and AS service issues that may arise. There is no need to contact individual manufacturers, which reduces management workload. And the final cost can be reasonably achieved with minimal lead time.

-

Reliable reference

Reliable referenceTechcross has extensive experience installing equipment on all types of ships, regardless of new buildings and existing ships. Engineers stationed at major bases around the world have acquired proficient skills through training centers and online educational materials to provide the best service.

-

Various installation solution

Various installation solutionBased on extensive experience, Techcross provides optimal installation solutions customized to the specific requirements of ships or customers. Techcross also contributes to maximizing customer benefits by offering various solutions, such as installing only the necessary equipment or directly installing it on a ship through container configurations.

-

Global network

Global networkThere are 6 local offices near major ports around the world, collaborating with over 40 partners in 21 countries, ensuring a 24-hour response system to address customer inquiries. The necessary materials are delivered promptly through a global supply network, and skilled engineers can also be dispatched directly.

Energy Saving Device .

There are ways to protect the environment and increase ship operation efficiency without building new environmentally friendly ships. By adding minimal auxiliary devices, it is possible to reduce hull resistance or improve navigation efficiency, ultimately allowing ships to cover more distance with less fuel. Techcross is here to assist you in achieving cost savings through these measures.

-

RUDDER BULB +

DIVERGENT PROPELLER CAPImprovement of propeller propulsion efficiency

Approximately 1.5 ~ 2.5% energy saving effectQuick return on investment (around 1 year)No separate maintenance during navigationNo interference with helm operations and compatible with various helm type -

HULL FIN

Reduction and improvement of hull resistance

Approximately 2 ~ 3% energy saving effectAbout 20% reduction in hull vibrationQuick return on investment (around 1 year)Compact size, quick and easy installation